What Is Event Tree Analysis (ETA)?

2025-04-22

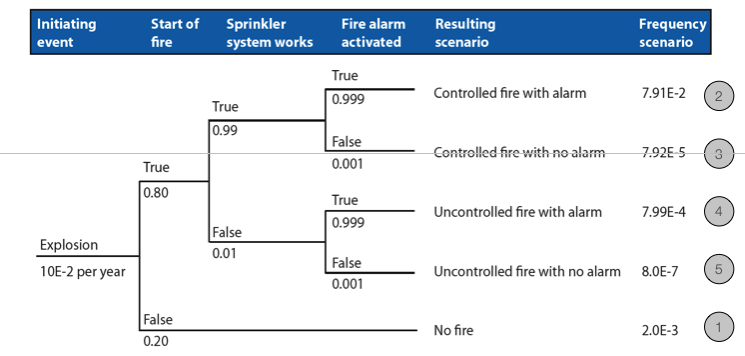

Event Tree Analysis (ETA) is a forward-looking risk assessment tool used to explore the different outcomes that can result from a single initiating event. It’s a structured, visual method that helps you answer the question:

ETA maps possible scenarios step by step, showing how protective systems and human actions influence the outcome.“If this goes wrong… what happens next?”

Why Use ETA?

ETA is widely used in industries such as:

-

Process industry

-

Nuclear plants

-

Chemical plant safety

-

Process and system hazard analysis (HAZOP follow-ups)

-

Functional safety (e.g., IEC 61508, ISO 26262)

-

Natural disaster modeling (e.g., rockslides and tsunamis)

Benefits of ETA:

-

Easy to understand and communicate.

-

Helps identify system weaknesses.

-

Supports compliance and safety design.

-

Can be qualitative or quantitative.

Key Concepts: Initiating & Pivotal Events

-

Initiating Event (IE): The first significant failure or disturbance (e.g., fire, system error).

-

Pivotal Events (PEs): Key points in the scenario where a safety function may succeed or fail.

-

End States: The possible outcomes (e.g., no damage, partial damage, catastrophic loss).

Each path through the tree represents a different scenario — each with its own risk level and probability.

Step-by-Step: How to Build an Event Tree

-

Define the Initiating Event

e.g., fire in a control room. -

List the piv0tal events

e.g., fire, wind direction, alarm, sprinkler, operator response, etc -

Map Out Each Success/Failure Point

Each decision branches the tree. -

Create All Paths to End States

Each path = a scenario. -

(Optional) Assign Probabilities

Use historical data or expert judgment. -

Analyze the Results

Identify critical failures, success paths, and improvement areas.

Real-World Example: Reactor Coolant Loss

This is based on nuclear risk modeling:

-

A small pipe crack causes coolant to leak.

-

The High Pressure Injection System (HPIS) must activate.

-

If it fails, the Low Pressure Injection System (LPIS) is next.

-

If LPIS also fails, the operator must act quickly.

-

Depending on what works and what fails, the outcome ranges from full recovery to core damage.

This scenario is often used in training and simulation across safety-critical industries.

ETA vs. Fault Tree Analysis (FTA)

| Feature | ETA | FTA |

|---|---|---|

| Logic Direction | Inductive (forward-looking) | Deductive (root cause focus) |

| Starts With | A trigger or failure event | A top-level system failure |

| Focus | Scenario outcomes | Cause diagnosis |

| Best For | Understanding consequences | Tracing failure origins |

Tip: They are often used together! FTA informs probabilities that feed into ETA.

How ETA Supports Better Decision-Making

ETA helps you:

-

Design more resilient systems

-

Visualize worst-case and best-case scenarios

-

Support functional safety assessments (SIL, LOPA)

-

Improve operator training and simulations

-

Prioritize mitigation strategies

-

Communicate complex risk scenarios to stakeholders

Final Thoughts

Event Tree Analysis is a simple yet powerful tool. Whether you're working in process safety, energy, manufacturing, or infrastructure — ETA helps you prepare for the unexpected, communicate risk, and make better decisions.

At Risknowlogy, we believe in making complex safety tools understandable, accessible, and actionable. Contact us online or via WhatsApp.